Product

Yibike air-cooled machine room dedicated air conditioner

Yibike air-cooled machine room dedicated air conditionerEUA013A Technical Spec

Yibike air-cooled machine room dedicated air conditionerEUA013A

Technical Specifications

Catalogue

1. summary

1.1. describe

1.2. Design standards

1.3. Application scope

2. Product Introduction

Product Introduction

Product Features

3. Technical Parameter

4. Main component configuration list

5. Installation Requirements

5.1Usage environment

5.2Installation requirements for outdoor indoor units

5.3Specification for refrigeration connecting pipes

5.4Electrical specifications

1. summary

1.1. Explanation

This technical specification is applicable to the air-cooled machine room dedicated air conditioning produced by Guangdong Yibike Energy Technology Co., Ltd. It aims to standardize the technical parameters, main component configuration, installation requirements, etc. of the product, as a guide for market sales, technical support and other related work. Guangdong Yibike Energy Technology Co., Ltd. reserves the right of final interpretation of this technical specification. When using this technical specification, please confirm with relevant personnel.

1.1. Design Standards

The products involved in this technical specification mainly follow the following standards::

GB/T19413 《Unit air conditioning units for computer and data processing rooms》

GB4706.1 《Safety of household and similar electrical appliances - Part 1: General requirements》

GB4706.32 《Safety of household and similar electrical appliances - Special requirements for heat pumps, air conditioners, and dehumidifiers》

GB5226.1 《Mechanical and electrical safety - Mechanical and electrical equipment - Part 1: General technical specifications》

GB9237 《Safety requirements for mechanical refrigeration systems used in refrigeration and heating》

GB/T17758 《Unitary air conditioners》

GB25130 《Safety requirements for modular air conditioning units》

GB50736 《Design Code for Heating, Ventilation and Air Conditioning of Civil Buildings》

GB50243 《Code for Acceptance of Construction Quality of Ventilation and Air Conditioning Engineering》

GB50174 《Design Specification for Electronic Information System Room》

1.1. Scope of Application

The products involved in this technical specification are suitable for various places that require constant temperature and humidity environments: computer rooms, data centers, program-controlled exchange rooms, satellite mobile communication stations, medical equipment rooms, laboratories, precision electronic instrument production workshops, etc。

Product Introduction

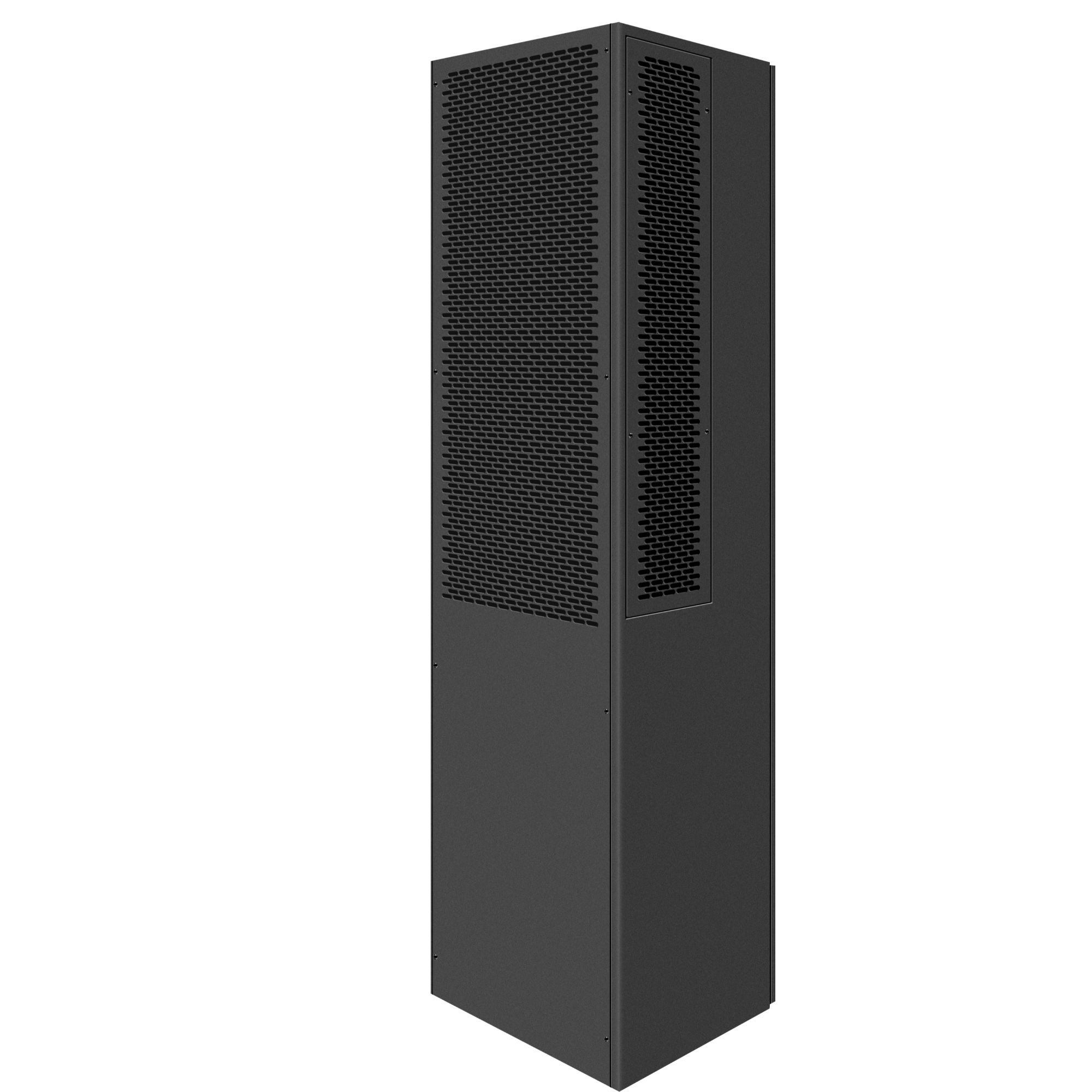

The dedicated air conditioning for the data center is designed by Guangdong Yibike Energy Technology Co., Ltd. for IDC data centers and communication base stations that operate 24 hours a day, 365 days a year without interruption. The unit operates smoothly, safely and reliably, ensuring that the equipment in the computer room operates in the most suitable environment for a long time。

The unit adopts a frame structure design, and all components can be easily repaired or replaced from the front and both sides of the unit. But in order to ensure the cooling effect, the distance between the two sides and the back of the unit and the wall should be greater than 400mm. Unit air supply method: forward air supply。

Product Features

The unit has control functions for cooling, heating, and dehumidification, and the temperature and humidity can be set. The system can operate according to the set indoor temperature and humidity status. The control of various functions can ensure that they are within the set control points and precision control range。

Temperature regulation range:+16 ℃~+40 ℃, temperature regulation accuracy: 1 ℃;

Humidity regulation range: 20% to 95% RH, humidity regulation accuracy: 5% RH.

1) Refrigeration

Adopting a direct expansion refrigeration cycle, with high energy efficiency, high reliability, and low operating costs, it meets the requirements of "green environmental protection".

2) Dehumidification

The unit automatically controls the fan speed according to the room requirements, thereby accurately controlling the dehumidification capacity of the unit. Rapid dehumidification can greatly improve the accuracy of humidity control.

3) Reheating (optional function)

When the system needs dehumidification, the unit can start electric heating for cooling compensation according to the demand. The unit is equipped with PTC electric heaters and has overheat protection function.

4) Humidification (optional function)

Using an electrode humidifier to achieve 30% to 100% humidification output.

5) Group control

Support centralized control of multi unit networking, while also having rotation and backup functions.

6) Remote monitoring

Support remote monitoring, provide RS485 interface, and support MODBUS protocol. Capable of three remote functions: telemetry, remote control, and remote signaling.

7) Alarm protection

Fan fault alarm, electric heater overload alarm, humidifier fault alarm, phase sequence protection alarm, system high/low voltage protection alarm, filter blockage alarm, high/low temperature alarm, etc.

8) Other functions

The unit has functions such as manual/automatic operation control, rotation and backup, fault self diagnosis, fault alarm record storage, power-off storage/automatic recovery/incoming call self start, multi-level password, etc; And it can record the cumulative working time of compressors, fans, humidifiers, and heaters.

1. 2. Technical parameters

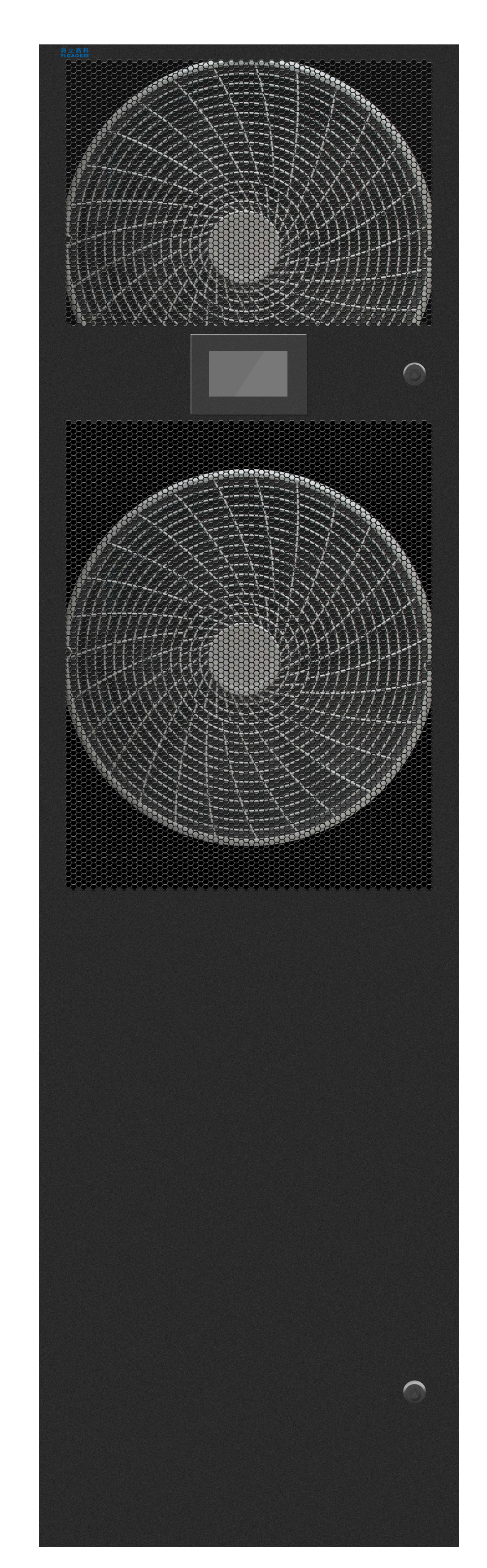

model power supply air supply mode | EUA013A 380V/3PH/50Hz Step forward and provide air supply | |

Refrigeration capacity Total cooling capacity sensible cooling capacity |

kW kW |

13 12.22 |

Indoor fan Number of fans Circulating air volume fan power |

Tower m3/h W | DCfan 2 3500 100 |

Compressor form Number of compressors | rotor type 1 | |

Humidification amount Humidification power | kg/h kW | 3 2.2 |

Electric heater | kW | 3 |

Indoor fan noise | dB(A) | 58 |

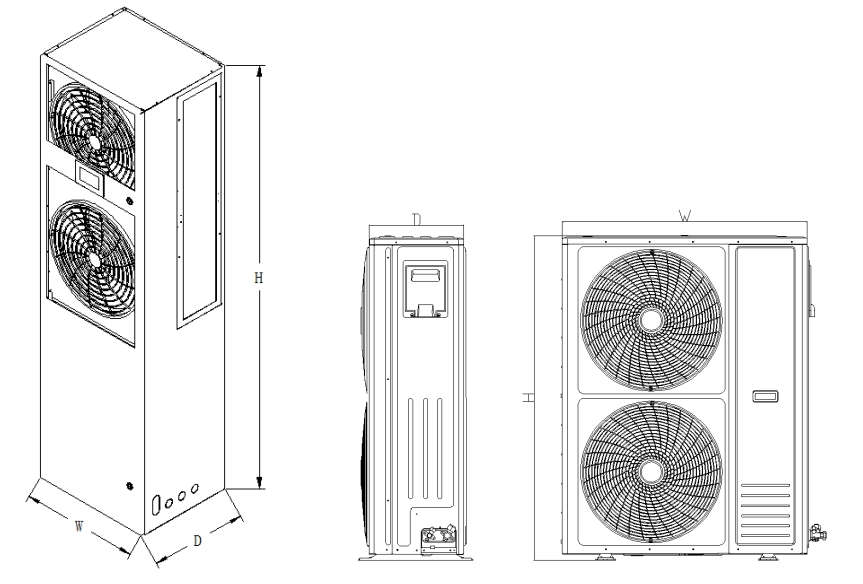

External dimensions Width (W) Deep (D) High (H) |

mm mm mm |

510 425 1865 |

weight | kg | 108 |

take overRefrigerant pipeline:exhaust/Liquid tube Condensate drainage Humidifier inlet/outlet |

mm mm mm |

16/9.52 21 19/32 |

Outdoor | ||

quantity | tower | 1 |

model | ECA019 | |

Heat exchange capacity | kW | 19 |

Rated air volume | m3/h | 7000 |

Number of fans | 个 | 2 |

Rated power (per fan) | W | 175 |

External dimensions Width (W) Deep (D) High (H) |

mm mm mm |

960 370 1260 |

weight | kg | 53 |

1. 3. List of Main Component Configuration

SeriaNumberl | Component Name | Manufacturer, brand | model | quantity | origin | notes |

1 | compressor | HIGHLY | ATH489UC3C9EQC | 1 | Shanghai | |

2 | Indoor fan | Kaibang Motor+Shunwei Fan Leaf | ZWR40-D55+ Φ400 | 1 | Zhuhai, Foshan | |

3 | Outdoor fan | Junfeng | 175 | 2 | Foshan | |

4 | expansion valve | three flowers | DPF(TS1)2.4C | 1 | Hangzhou | |

5 | controller | Ailiwei | HAC02M3 | 1 | Sichuan | |

6 | monitor | Ailiwei | HAC02D1Z colorful touch screen | 1 | Sichuan | |

7 | temperature and humidity sensor | Ailiwei | HAC02S1 | 1 | Sichuan | |

8 | Humidifier tank | Huaxia Ruichi | RSD-02 | 1 | Beijing | Optional |

9 | Electric heater | East | PTC 3kW | 1 | Zhejiang | Optional |

10 |

1. Installation requirements

5.1Usage environment

Operating environment requirements

The operating environment of the unit meets the requirements of GB4798.3 "Environmental Conditions for Application of Electrical and Electronic Products"

project | specific requirement |

ambient temperature | indoor:16℃~40℃ outdoor:-15℃~45℃ |

ambient humidity | 20%~ 95%RH |

operating voltage | 380V(±15%)/3 Ph /50Hz |

protection grade | Indoor unit:IPX0,Outdoor:IPX4 |

altitude | <1000m 大于1000m Reduced usage |

Storage environment requirements

The storage environment of the unit meets the requirements of GB4798.1 "Environmental Conditions for Application of Electrical and Electronic Products - Storage"

project | specific requirement |

Stored Environment | Stored indoors, clean and dust-free, etc |

ambient temperature | -20℃~54℃ |

ambient humidity | 5%~95%RH |

storage time | The total transportation and storage time shall not exceed 6 months, and the performance shall be recalibrated after 6 months |

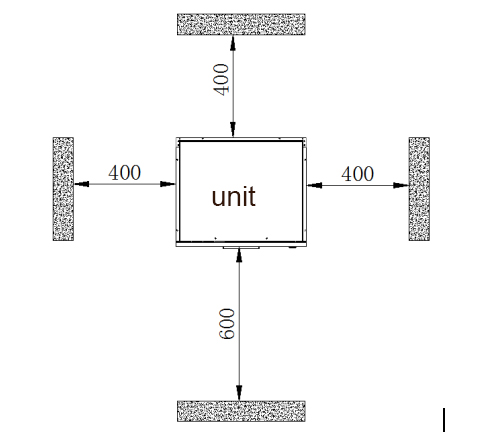

5.2Installation requirements for outdoor indoor units

l At least 600mm of operating space should be reserved on the front of the indoor unit, and no less than 400mm of operating space should be reserved on both sides and the back;

l Outdoor units can only be installed vertically;

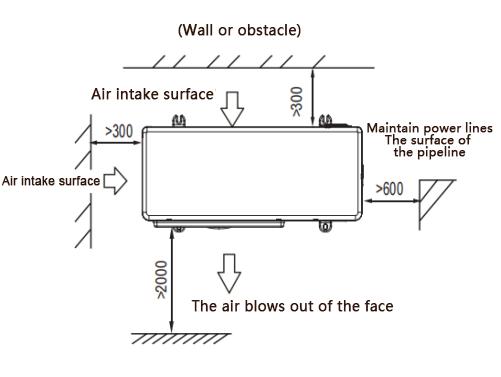

l There should be no obstructions within 2m in front of the outdoor unit's air outlet, 0.3m on the left and back, and 0.6m on the right to ensure smooth ventilation;

Vertical installation diagram of outdoor unit

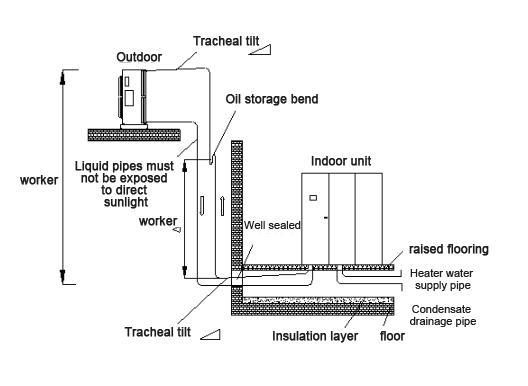

5.3 Specification for refrigeration connecting pipes

Specification and size table of connecting pipes (indoor and outdoor connecting pipe length within 30 meters):

tracheal diameter(mm) | Liquid tube diameter(mm) | Diameter of condensate drain pipe(mm) |

16 | 9.52 | 21 |

The installation dimensions of the outdoor unit are higher than those of the indoor unit, as shown in the diagram

5.1

parameter | Dimensions |

H | ≤20m |

△H | Every increase6m |

tilt | 1/100 |

The installation size table for outdoor units is lower than that for indoor units, as shown in the figure

5.2

parameter | Dimensions |

H | ≤5m |

tilt | 1/100 |

picture5.1 Installation diagram for outdoor unit higher than indoor unit

picture5.2 Installation diagram for outdoor unit lower than indoor unit

5.4 Electrical specifications

model | EUA013A(No heating humidification) | EUA013A(Heating and humidification) |

Maximum current(A) | 12 | 15 |

Powercord diameter(mm2) | 5*2.5 | 5*4.0 |

Air Switch(A) | 16 | 25 |